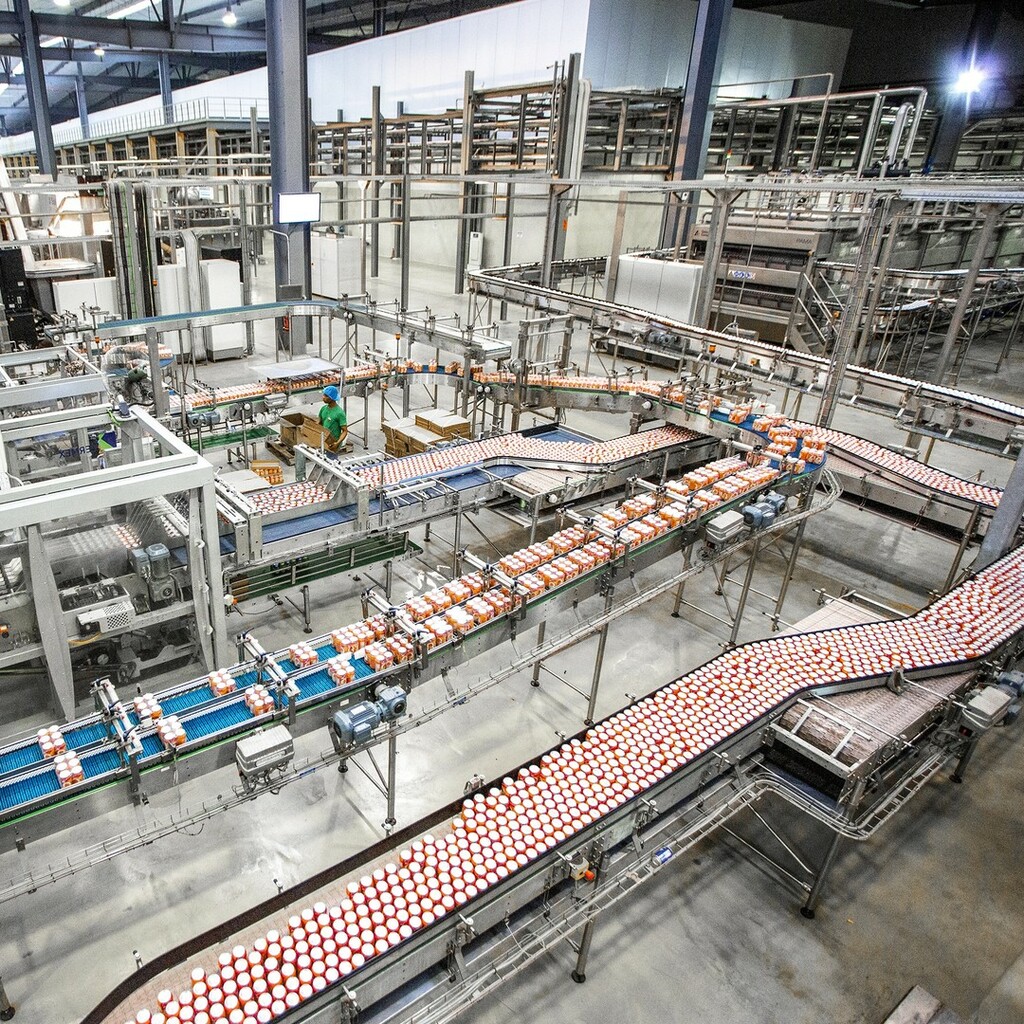

Complete Line Installation by BevTech: Seamless Setup for Your Facility

At BevTech, we specialize in complete line installation for your production facility, whether you're relocating existing lines or installing new ones. Our expertise in managing end-to-end installation processes ensures that your equipment is set up efficiently, safely, and according to your specific requirements.

Why Choose BevTech for Line Installation?

We are committed to providing you with a smooth and hassle-free experience when it comes to installing your production line. Here’s what makes us the best choice:

1. Expertise in Relocation & New Installations

Whether you're moving existing machinery to a new location or setting up an entirely new production line, BevTech has the technical knowledge and experience to get the job done. Our team handles the complexities of logistics, dismantling, reassembling, and setting up equipment, ensuring minimal downtime for your operations.

2. Comprehensive Machine Installation Services

Our trained service technicians are skilled in working with various types of production equipment, including:

Blowmolding Machines: Precise setup for high-quality bottle and container production.

Filling Machines: Accurate filling setups for consistent output.

Labelers: Efficient installation of labeling systems for smooth packaging processes.

Packers & End of Line Equipment: Proper installation of packing machines to streamline packaging workflows.

We ensure that every component of your line is installed with care, making it fully operational to meet your production demands.

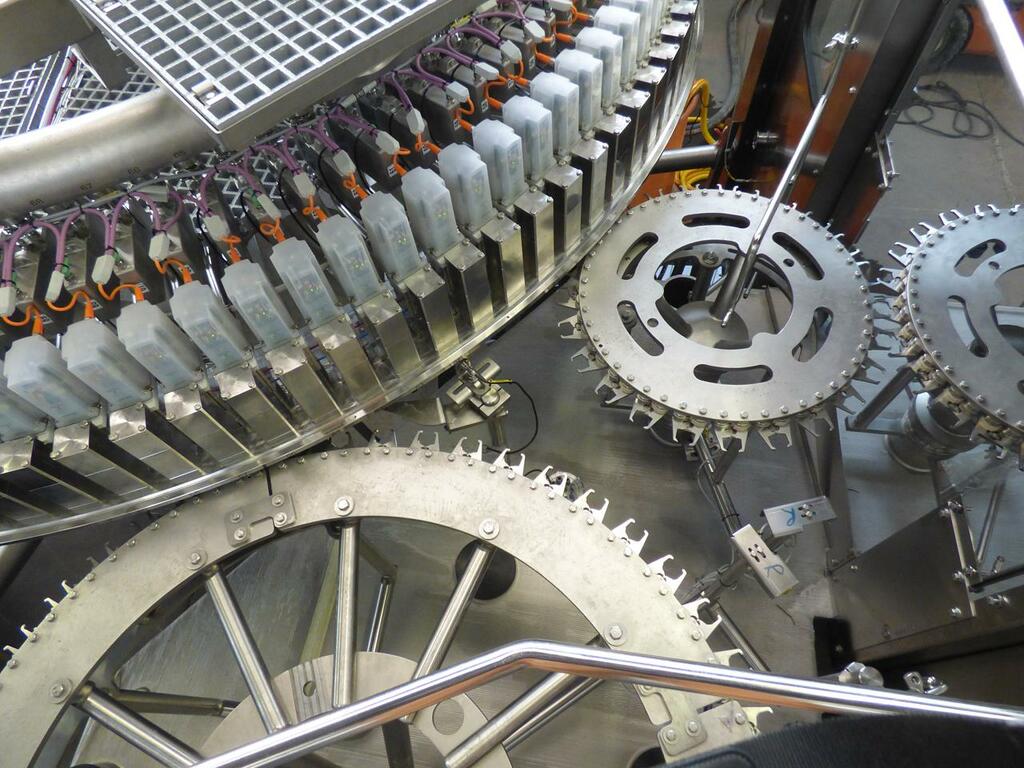

3. Careful Handling and Staging

At BevTech, we prioritize the safe and careful handling of your equipment. Our process begins when the shipment arrives at your facility. We make sure that all machinery is removed from containers carefully and staged properly for installation. This step is crucial to prevent any damage and ensure that the machinery is ready for setup.

4. Tailored Installation with Skilled Engineers

Once your equipment is staged, our team of skilled engineers works closely with you to install the machines according to your plant’s layout. We take time to understand your space requirements and production needs, ensuring that each machine is positioned for optimal performance. Our installation includes:

Electrical Connections: All electrical components are connected with precision, ensuring smooth and safe operation.

Pipe Welding: We perform any necessary welding of pipes to ensure proper fluid flow throughout the line.

5. System Startup & Quality Assurance

Once installation is complete, we conduct a thorough startup process to ensure that every machine is running as expected. Our team tests all components, verifies performance, and fine-tunes settings to meet your specifications. Only when we’re confident that the line is operating flawlessly do we hand over the system to you.

6. Ongoing Service & Support

At BevTech, our commitment to your success doesn’t end with the installation. We offer continued service and support for the lifetime of your equipment, ensuring that your production line remains in optimal working condition. From routine maintenance to troubleshooting, our team is always available to assist you.

Get Started with BevTech Today

Whether you’re installing a new line or relocating an existing one, BevTech provides professional, reliable, and timely services to ensure your production equipment is set up for success. Our skilled technicians and engineers are ready to assist you with all your line installation needs. Contact us today to discuss how we can support your production facility with seamless installation and exceptional service.